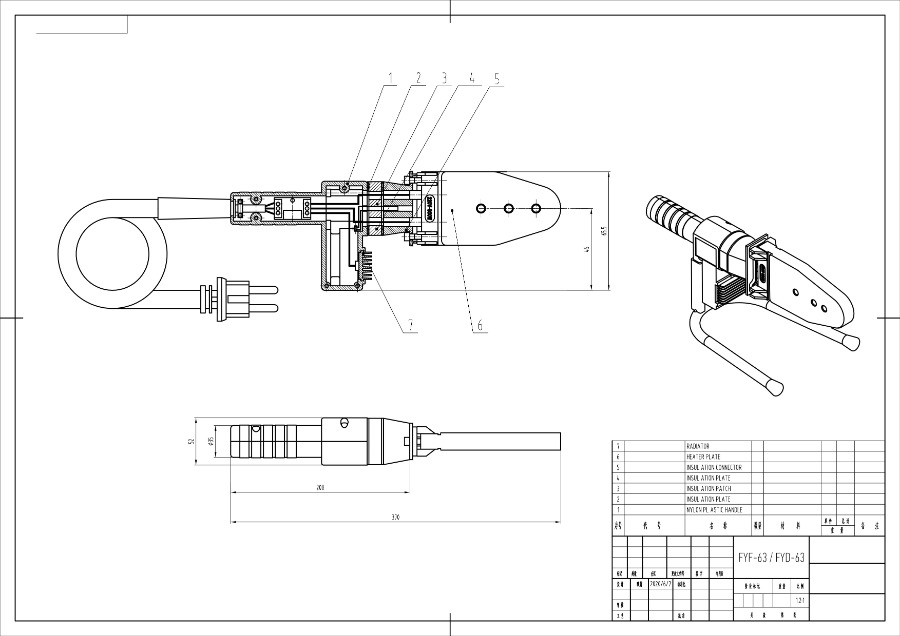

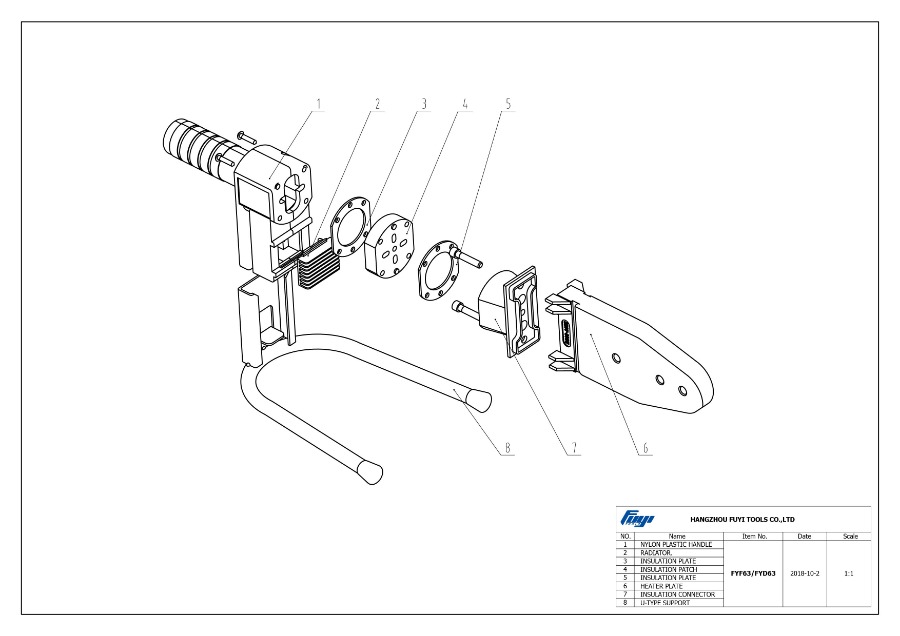

Constant Temperature Socket Fusion Welding Machine

FYF63 Constant Temperature Socket Plastic PPR Pipe Welder

The FYF63 Constant Temperature Socket Plastic HDPE PPR Pipe Welder is an advanced welding machine designed for the fusion welding of plastic pipes, specifically High-Density Polyethylene (HDPE) and Polypropylene Random Copolymer (PPR) pipes. This welding equipment operates on the principle of maintaining a constant temperature during the welding process, ensuring the seamless and durable connection of plastic pipes in various applications.

This welding machine is equipped with a sophisticated temperature control system, which is the key feature responsible for maintaining a constant temperature throughout the welding process. The system is designed to precisely regulate the temperature needed for the fusion of HDPE and PPR pipes. The control panel provides an intuitive interface for the operator to set and monitor the desired temperature, ensuring the accuracy and consistency of the welding operation.

The FYF63 Constant Temperature Socket Plastic HDPE PPR Pipe Welder operates on the principle of butt fusion welding, where the ends of the plastic pipes are heated to their melting point and then joined together under constant pressure. This results in a homogeneous and leak-proof connection that meets the stringent requirements of various industries, including water supply, gas distribution, and other applications where plastic pipes are commonly used.

In practical applications, this welding machine is widely employed in the construction of water and gas distribution systems, as well as industrial pipelines. Its ability to maintain a constant temperature during the welding process ensures the quality and integrity of the joints. The versatility of the Constant Temperature Socket Plastic HDPE PPR Pipe Welder allows it to be used with pipes of different diameters, providing a reliable solution for various pipe fusion requirements.

Eng

Eng  русский

русский Español

Español